Unforeseen parts scarcity and complex diagnoses can extend repair completion timelines for high-end vehicles like Mercedes Benz, impacting efficiency and customer satisfaction. Effective workflow management and seamless coordination with external contractors are crucial to avoid disruptions in collision repairs involving multiple specialized services. Misunderstandings and delays in scheduling can prolong the repair completion timeline, emphasizing the need for clear communication, detailed planning, flexibility, and aligned deadlines among all involved parties.

Extending the repair completion timeline is a common challenge for many businesses. This article delves into three primary factors contributing to these delays: unforeseen parts scarcity, complex diagnoses, and coordination issues with external contractors. By understanding these steps, facilities managers can better anticipate potential setbacks, optimize resource allocation, and ultimately streamline the repair process, ensuring faster completion times.

- Unforeseen Parts Scarcity Delays Repairs

- Complex Diagnoses Extend Timeline Significantly

- Coordination Issues with External Contractors

Unforeseen Parts Scarcity Delays Repairs

In many cases, the repair completion timeline is extended due to unforeseen parts scarcity, which can significantly delay even the most meticulously planned repairs. This issue frequently arises with specialized or high-end vehicle models like Mercedes Benz, where specific parts may not be readily available in local markets. The global supply chain for automotive components can sometimes face disruptions, leading to delays in acquiring necessary parts for dent repair or hail damage repair.

The impact of parts scarcity on repair completion timeline is profound. While mechanics and repair shops do their best to source alternative solutions, the search for suitable substitutes consumes time that could otherwise be dedicated to actual repairs. Consequently, customers facing these delays experience frustration and inconvenience, underscoring the importance of understanding potential delays in the repair process, especially when dealing with specialized vehicle types like Mercedes Benz or extensive damage from dent repair or hail damage repair.

Complex Diagnoses Extend Timeline Significantly

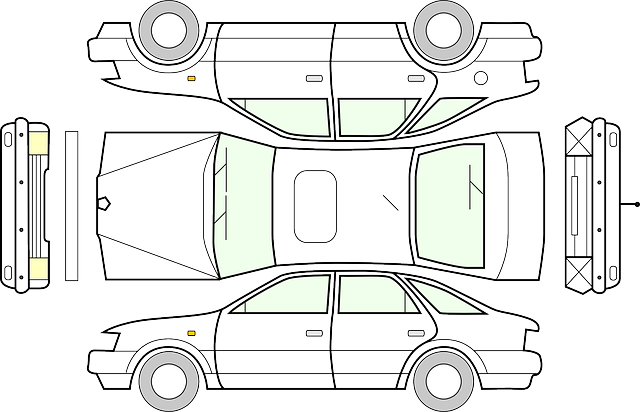

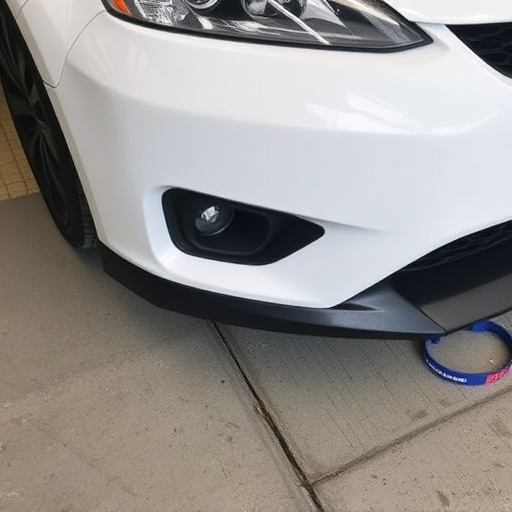

When it comes to repairs, complex diagnoses often lead to longer completion timelines. This is because issues that are not immediately apparent require more time and specialized knowledge to identify accurately. For instance, a car paint services technician may need to spend additional time assessing the extent of damage beyond the visible surface before proceeding with any restoration work. Similarly, collision repair center professionals dealing with structural damage must employ advanced diagnostic tools to ensure every component is safely and correctly addressed.

The complexity intensifies when it comes to coordinating various car repair services within a single job. For example, if a vehicle needs both body work and mechanical repairs, these tasks must be scheduled in a way that allows for efficient workflow without disrupting the overall timeline. Each specialized service demands dedicated attention, so managing these intricacies can significantly extend the repair completion timeline.

Coordination Issues with External Contractors

One significant challenge that can extend the repair completion timeline is coordination with external contractors. In the case of complex vehicle restoration or Mercedes Benz collision repair projects, multiple specialized teams may be involved. From painting and panel work to mechanical repairs and interior refurbishment, each contractor has their own schedule and processes. Ensuring seamless communication and alignment between these entities requires diligent project management. Misunderstandings, delays in scheduling, and conflicts in estimated timelines can all contribute to a prolonged repair completion timeline.

For instance, an auto body repair shop may need to coordinate with a painting service, a parts supplier, and a mechanical workshop. If any one of these parties faces unforeseen delays or has inconsistent communication, the entire process can be negatively impacted. Effective coordination involves clear and consistent communication channels, detailed planning, and flexibility to accommodate unexpected challenges. Ensuring that all contractors are aligned on deadlines, dependencies, and quality standards is crucial for meeting the desired repair completion timeline.

Extending the repair completion timeline is often unforeseen, but several factors can significantly impact the process. Scarcity of replacement parts, complex diagnoses requiring specialized knowledge, and coordination challenges with external contractors can all contribute to delays. By understanding these potential hurdles, homeowners and maintenance teams can better prepare for timely repairs, ensuring minimal disruption to daily life and keeping projects on track within the extended timeframe.