Implementing a repair completion timeline in fleet management optimizes efficiency and quality control for car body shops. This structured approach sets clear goals for each repair stage, from assessment to final check, enabling prompt service while ensuring accurate outcomes like scratch repairs, auto painting, and mechanical fixes. By managing multiple vehicles and intricate processes through streamlined workflows, specialized equipment, and open communication, shops meet tight deadlines and enhance customer satisfaction.

In the fast-paced world of fleet management, efficient repairs are non-negotiable. Fleet repairs adhere to a strict repair completion timeline, ensuring operations remain uninterrupted. This article delves into the intricate process, from understanding the significance of timely repairs to exploring key stages and tackling challenges. By dissecting each critical step, we uncover strategies that enable fleet managers to consistently meet deadlines, thereby optimising their vehicle’s uptime and overall efficiency.

- Understanding the Repair Completion Timeline

- Key Stages in Fleet Repair Process

- Meeting Deadlines: Challenges and Solutions

Understanding the Repair Completion Timeline

When it comes to fleet repairs, efficiency is key, and that’s where understanding and adhering to a strict repair completion timeline comes into play. This timeline acts as a structured framework ensuring repairs are completed promptly and effectively. It involves setting clear goals for each stage of the repair process, from initial assessment to final quality check. By doing so, fleet managers and repair technicians can anticipate potential delays, allocate resources efficiently, and meet tight deadlines.

The repair completion timeline is not just about speed; it also guarantees quality. Each step in the process has defined parameters, ensuring that repairs are done correctly, whether it’s fixing a car scratch repair, performing intricate auto painting tasks, or addressing more complex mechanical issues. This structured approach allows for better control, reduces human error, and ultimately, enhances customer satisfaction within the car body shop environment.

Key Stages in Fleet Repair Process

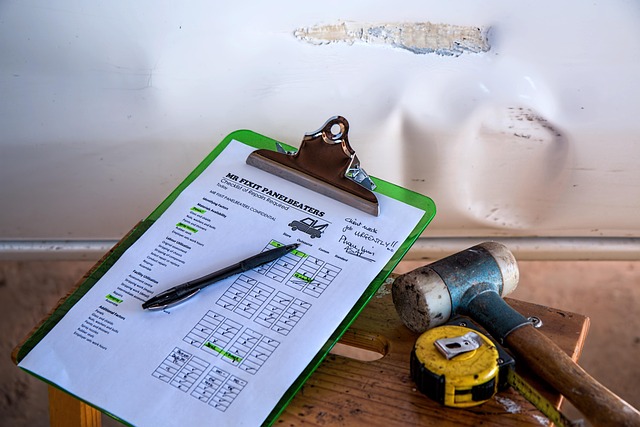

The fleet repair process is a well-structured, meticulous journey designed to get vehicles back on the road as efficiently and safely as possible. It involves several crucial stages that adhere to a strict repair completion timeline. The initial assessment determines the extent of damage, followed by disassembly and inspection, where every component is scrutinized for repairs or replacements. This meticulous evaluation ensures that only authorized parts—be it a simple car paint repair or intricate engine work—are used, maintaining the vehicle’s integrity.

Once the planning phase is complete, the actual repair begins. Skilled technicians, often specializing in various areas like bodywork, mechanical, or electrical systems, collaborate to bring the fleet back to its optimal condition. Regular quality checks during the repair process guarantee that each step aligns with industry standards and safety protocols. Finally, a comprehensive test drive ensures the vehicle’s roadworthiness before it leaves the collision center, upholding the reputation of professional automotive repair services.

Meeting Deadlines: Challenges and Solutions

Meeting deadlines is a cornerstone of successful fleet repairs, yet it presents unique challenges. Automotive body shops must juggle multiple vehicles with diverse repair needs, often involving complex processes that require precise timing. Streamlining workflows, utilizing specialized equipment, and fostering open communication become essential strategies.

Effective coordination among technicians, parts suppliers, and managers is crucial to overcoming delays. Fleet repair services can implement robust tracking systems for orders and inventory, ensuring that every step of the repair completion timeline is met. Additionally, prioritizing urgent repairs and employing experienced staff adept at automotive collision repair can significantly mitigate potential setbacks, allowing for consistent delivery of high-quality work within the set deadlines.

Fleet repairs, guided by a strict repair completion timeline, are a well-structured process designed for efficiency. By understanding the key stages and addressing challenges head-on, fleet managers can ensure timely completion without compromising quality. Adhering to this structured approach, including meticulous planning and effective communication, allows for optimized vehicle uptime and cost savings. Thus, managing fleet repairs with a focused eye on the repair completion timeline is a vital strategy for any operation seeking both operational excellence and financial sustainability.